A clean room is a contaminate-, bacteria-, and microorganism-free environment structured to contain and eliminate harmful particulates that may damage a process or test. For many years, these special rooms were built into buildings and had strict codes for clothing, air, appliances, and testing methods. As with many other aspects of society, clean rooms have become a necessity in conditions that reach beyond their original purpose but with the same constraints. Read More…

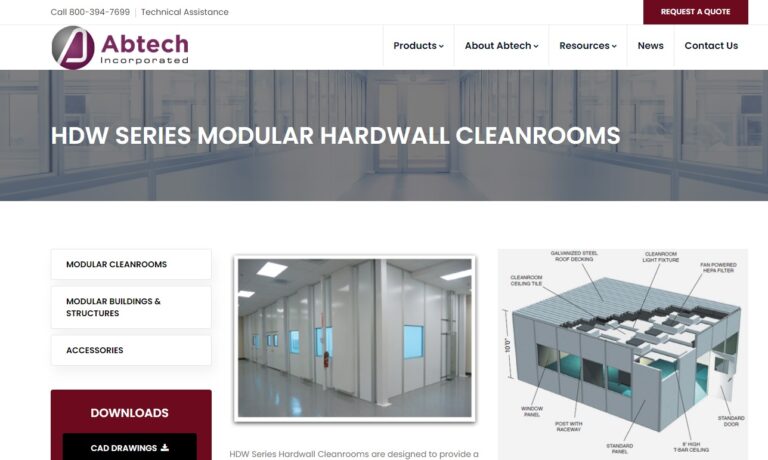

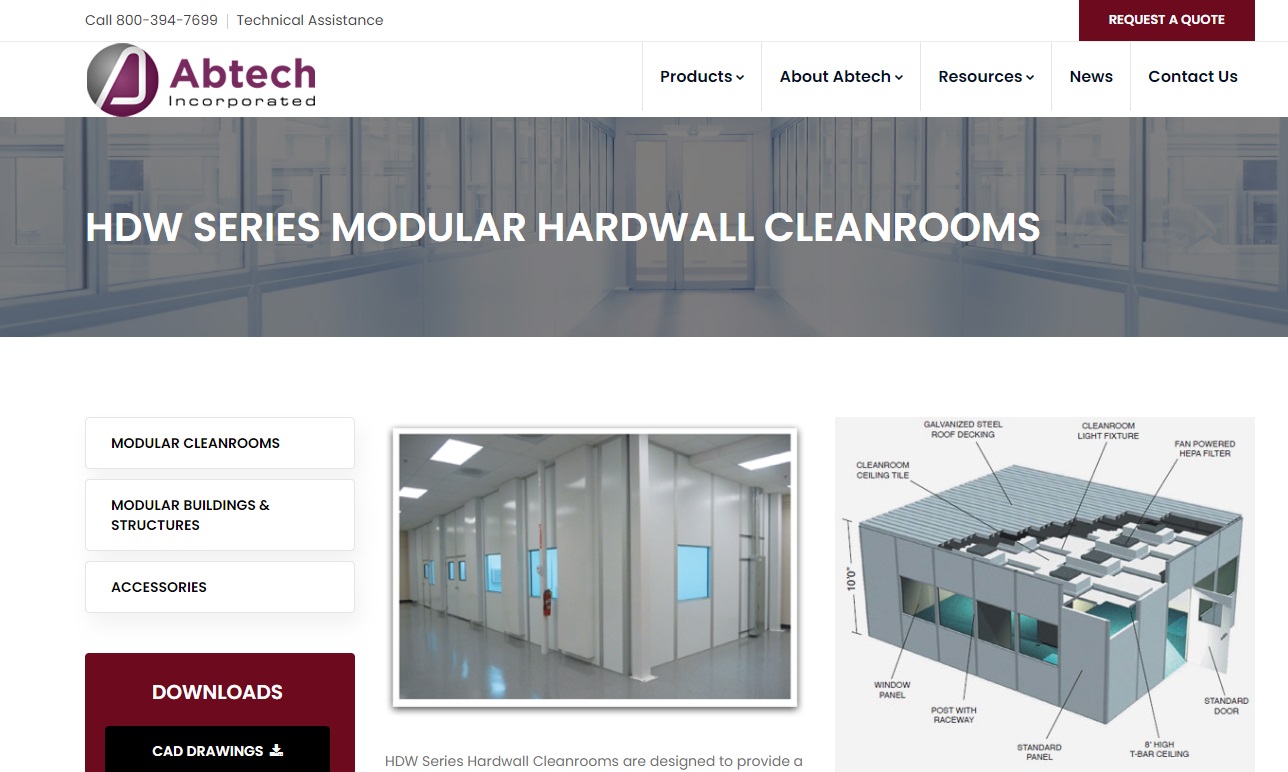

As a manufacturer of clean rooms, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

For the very best of clean rooms, look no further than Clean Rooms International! We can provide the ultimate in quality, customer service, durability, and unique designs just for you!

Cleanrooms By United is the industry’s premier manufacturer of modular clean room systems. We design, manufacture and install our clean rooms to meet our customers’ unique requirements. The custom, flexible, modular construction of our cleanrooms makes them easy to expand, reconfigure, or relocate as your cleanroom needs evolve.

Atmos-Tech Industries is a designer and manufacturer of cleanrooms and equipment for industries, including health care, pharmaceutical aerospace and automotive.

At MayAir Inc., we specialize in designing, engineering, and manufacturing high-performance clean rooms tailored to meet the most stringent contamination control requirements. With years of expertise, we provide comprehensive clean room solutions for various industries, including pharmaceuticals, electronics, biotechnology, and healthcare.

Our complete line of clean rooms will meet your needs. We are the experts of the clean room industry and our engineers can work with you to determine which clean room models work best for your business. We offer a variety of softwall, bio-clean, hardwall, and micro-clean options, all of which are manufactured with the highest standards. You will not be upset with our products. Contact us for more ...

Since 1976, we at Mitchell Technical Sales have been dedicated to delivering excellence in quality cleanroom design, manufacturing, installation, certification, and maintenance. Our journey has been marked by innovation and expertise, ensuring that every project we undertake reflects our commitment to precision and cutting-edge solutions.

More Portable Clean Rooms Manufacturers

Unique situations have led to the development of clean rooms that can be positioned anywhere in any environment, but still provide the same high cleanliness standards expected of permanent clean rooms. These compact, mobile, and convenient clean room units are referred to as portable clean rooms. They come in a wide range of sizes andISO classifications.

What is a Portable Clean Room?

A portable clean room is a compact mobile clean room that is able to provide a contaminate-free environment in a small space at low cost. They have all of the elements of larger clean rooms in order to be classified as a clean room, such as air filtration, walls, flooring, ceilings, and lighting. These required components are downsized to be portable and easily assembled.

To achieve clean room status, environments have to meet the standards established by the International Organization for Standardization (ISO) and United States Federal Standard 209, which have developed code designations to identify the proficiency of a clean room. The construction of portable clean rooms makes them incapable of reaching the highest classification and restricts them to Class 5 and above.

Types of Portable Clean Rooms

The first difference between portable clean rooms is the types of walls, which can be hard or soft walls. Either wall type makes it possible to place a disinfected enclosure close to production for efficient completion of operations and assembly. In some cases, hardwall portable clean rooms are more difficult to move and install than softwall portable clean rooms due the nature of the hardwall panel.

Softwall Portable Clean Rooms

Softwall clean rooms are an exceptionally flexible and cost effective way for creating a hygienically clean environment. A major benefit of softwall clean rooms is how easily they can be expanded as the need of an operation increases and how easily they can be deconstructed. Additionally, softwall clean rooms can be quickly placed on or near an assembly application to avoid the need to move goods to and from the controlled environment.

The structure of a softwall clean room consists of a frame made of aluminum or coated steel on to which the softwalls, made of vinyl, PVC, or other plastic strips, are hung. The nature of the work that is performed in a softwall clean room requires that the materials used to construct them be durable and long lasting.

Hardwall Portable Clean Rooms

Hardwall portable clean rooms have portable demountable hardwall panels that are placed in a frame similar to a softwall clean room. They are tightly sealed rooms that are very effective in keeping contaminants and airborne particles out. An advantage of hardwall clean rooms is their ability to be used for applications that require precision temperature and humidity control.

The panels for hardwall portable clean rooms are made of sealed and coated materials to keep them from being damaged during installation and removal. The frame and structure of hardwall portable clean rooms makes it possible to expand them and deconstruct them in accordance with the needs of manufacturing. As with softwall portable clean rooms, hardwall portable clean rooms are designed for continuous and long-term use.

Major Components of a Portable Clean Room

There are various factors used to classify a clean room, the most important of which is the particulate content of the air. In order to achieve a classification, filters, air handling units, walls, floors, and ceilings must meet the required standards of a classification. This necessitates the use of a specific set of components and materials.

High Efficiency Particulate Air (HEPA) Filters

HEPA filters are used in all clean rooms due to their ability to remove 99.97% of particulate matter as small as 0.3 micron (μ). In portable clean rooms, HEPA filters are installed in accordance with the type of air flow of the clean room, which can be single pass or recirculating, as well as the type of venting system.

Light Fixtures

Light fixtures can be the most complicated aspect of a portable clean room since they have to meet ISO lighting standards and be positioned such that they do not interfere with the air flow system. An increase in the amount of light decreases the efficiency of air flow but must meet the lighting needs.

The factor used to determine the amount of light is foot candle (fc), which is one lumen per square foot with lumens referring to the light output. The fc in portable clean rooms varies between 30 fc and 100 fc depending on the type of work being completed. Lighting for portable clean rooms is most commonly LED or fluorescent lamps.

Portable Electricity

A requirement for all clean rooms is an appropriate supply of electricity, which is necessary for testing and assembly applications. Portable clean rooms come with a complete supply of electricity built into the room such that it simply has to be plugged into an available outlet. The electrical system for a portable clean room is 120/208 three phase higher voltage for the air handling system. In special cases, generators can be added to the system as backup.

Benefits of Portable Clean Rooms

As technology has been rapidly advancing and controlled environments have become more of a necessity, portable clean rooms have been found to be the ideal solution for several industries. This is especially true for industries that normally do not need a sanitized environment.

- Damage Control – Portable clean rooms can be positioned close to assembly areas to avoid multiple handling operations such as loading and unloading. When a production process involves the need of a clean room, a portable clean room can be brought to the assembly area, which helps in efficiency and productivity.

- Floor Space – Permanent clean rooms take up floor space and are costly to maintain. Portable clean rooms have a very small footprint and can be disassembled when not needed.

- Low Cost – Portable clean rooms are available to be used within hours and made of lightweight sturdy materials that require fewer workers to assemble.

- Durability – A crucial factor for all materials used in a manufacturing or industrial setting is durability. It is for this reason that portable clean rooms are made of materials that will not corrode, rust, or deteriorate. In many cases, portable clean rooms are as long lasting as hardwall permanent clean rooms.

- Customization – Portable clean rooms can be configured to meet the space and equipment requirements of any industry regardless of how complex. It is for this reason that they have become so widely used in the technological age.

Portable clean rooms are another flexible tool that can assist in the development and production of products. Their use guarantees the quality of a product and customer satisfaction.

Choosing the Proper Portable Clean Room Manufacturer

To ensure the most positive outcome when purchasing a portable clean room from a portable clean room manufacturer, it is important to compare several companies using our directory of portable clean room manufacturers. Each portable clean room company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each portable clean room business website using our proprietary website previewer for an idea of what each company specializes in. Then use our simple RFQ form to contact multiple portable clean room businesses with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services