What is a cleanroom classification?

A cleanroom must meet the standards of the International Organization of Standardization (ISO) in order to be classified. The ISO, founded in 1947, was established in order to implement international standards for sensitive aspects of scientific research and business practices, such as working with chemicals, volatile materials, and sensitive instruments. Though the organization was created voluntarily, the standards established have set foundational principles in place that are honored by organizations worldwide. Today, the ISO has over 20,000 standards for companies to use as a guide.

The first cleanroom was developed and designed by Willis Whitfield in 1960. The design and purpose of a cleanroom is to protect its processes and contents from any outside environmental factors. The people who use the room and the items that are tested or constructed in it may hinder a cleanroom from meeting its standards of cleanliness. Special controls are required to eliminate these problematic elements as much as possible.

A cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles per cubic volume of air. The units begin at ISO 1 and go to ISO 9, with ISO 1 being the highest level of cleanliness while ISO 9 is the dirtiest. Most cleanrooms fall into the ISO 7 or 8 range.

International Organization of Standardization Particulate Standards

| Class | maximum particles/m3 | FED STD 209E equivalent |

|||||

| >=0.1 µm | >=0.2 µm | >=0.3 µm | >=0.5 µm | >=1 µm | >=5 µm | ||

| ISO 1 | 10 | 2 | |||||

| ISO 2 | 100 | 24 | 10 | 4 | |||

| ISO 3 | 1,000 | 237 | 102 | 35 | 8 | Class 1 | |

| ISO 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | Class 10 | |

| ISO 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 | Class 100 |

| ISO 6 | 1,000,000 | 237,000 | 102,000 | 35,200 | 8,320 | 293 | Class 1,000 |

| ISO 7 | 352,000 | 83,200 | 2,930 | Class 10,000 | |||

| ISO 8 | 3,520,000 | 832,000 | 29,300 | Class 100,000 | |||

| ISO 9 | 35,200,000 | 8,320,000 | 293,000 | Room Air | |||

Federal Standards 209 E – Cleanroom Standards Classifications

| maximum particles/m3 | |||||

| Class | >=0.5 µm | >=1 µm | >=5 µm | >=10 µm | >=25 µm |

| Class 1 | 3,000 | 0 | 0 | 0 | |

| Class 2 | 300,000 | 2,000 | 30 | ||

| Class 3 | 1,000,000 | 20,000 | 4,000 | 300 | |

| Class 4 | 20,000 | 40,000 | 4,000 | ||

How to keep a clean room classification

Since the purpose of a cleanroom is to study or work on delicate and fragile components, it would seem very unlikely that a contaminated item would be inserted into such an environment. However, there is always a risk, and steps must be taken to control it.

There are two variables that can lower a cleanroom’s classification. The first variable is the people who use the room. The second is the items or materials that are brought into it. Regardless of the dedication of a cleanroom staff, errors are bound to happen. When in a hurry, people may forget to follow all of the protocols, wear inappropriate clothing, or neglect some other facet of personal care.

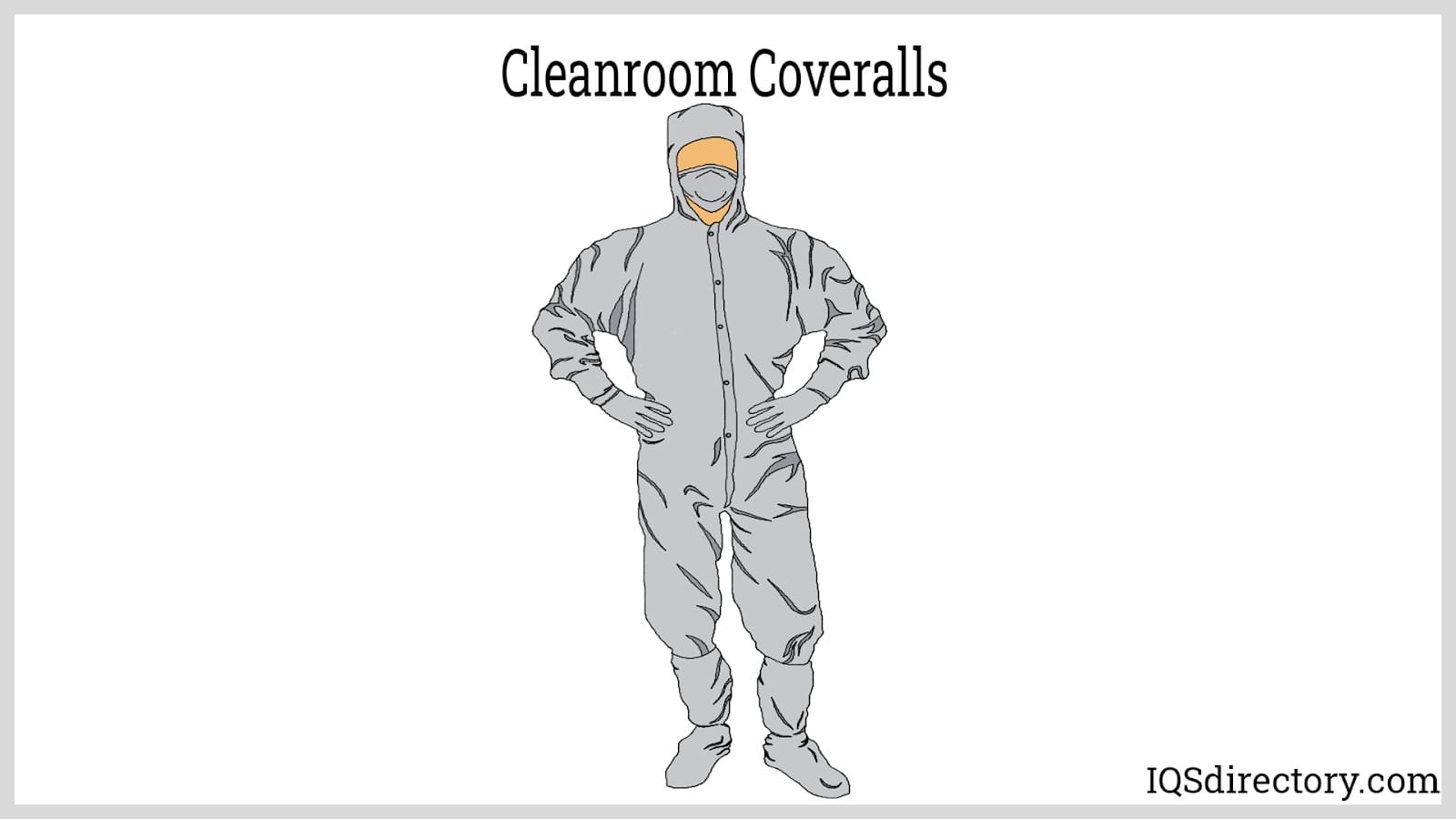

In an attempt to control these oversights, companies have requirements for the type of attire cleanroom staff must wear, which is affected by the required processes in the cleanroom. Normal cleanroom attire involves foot coverings, caps or hair nets, eye wear, gloves and a gown. The strictest standards stipulate the wearing of full-body suits that have a self-contained air supply that prevents the wearer for contaminating the cleanroom with their breath.

Problems of maintaining a cleanroom classification

The quality of the air circulating system in a cleanroom is the most significant problem related to maintaining a cleanroom classification. Even though a cleanroom has already received a classification, that classification can easily change or be lost altogether if it has a poor air filtration system. The system greatly depends on the number of filters required and the efficiency of their air flow.

One major factor to be considered is the cost, which is the most significant part of maintaining a cleanroom. In planning to build a cleanroom to a specific standard, manufacturers need to take a few things into consideration. The first item is the number of filters that are required to preserve the room’s air quality. The second item to consider is the air conditioning system to ensure that the temperature inside the cleanroom remains stable. Finally, the third item is the design of the room. In too many cases, companies will ask for a cleanroom that is larger or smaller than what they require. Therefore, the design of the cleanroom must be carefully analyzed so that it meets the exact requirements of its intended application.

What industries require the strictest cleanroom classifications?

As technology advances, there are crucial factors related to the production of technical devices. One of the major issues is the control of miniscule elements that may upset the operation of a sensitive device.

The most obvious need for a contaminate-free environment is the pharmaceutical industry where vapors or air pollutants could corrupt the manufacture of a medicine. Industries that produce intricate miniature circuits for precise instruments must be assured that the manufacturing and assembly is protected. These are only two of the many industries the use cleanrooms. Others are aerospace, optics, and nanotechnology. Technical devices have become smaller and more sensitive than ever before, which is why cleanrooms will continue to be a critical item in effective manufacturing and production.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services