Cleanrooms are specialized environments designed to control the concentration of airborne particles and other contaminants. These rooms are commonly used in industries such as pharmaceuticals, biotechnology, and aerospace to prevent contamination during the manufacturing, assembly, or testing of products. The classification of a cleanroom is based on the maximum allowable concentration of particles per cubic meter of air. Class 1000 cleanrooms, for example, have a maximum particle count of 1,000 particles per cubic foot of air, making them suitable for a wide range of applications. Read More…

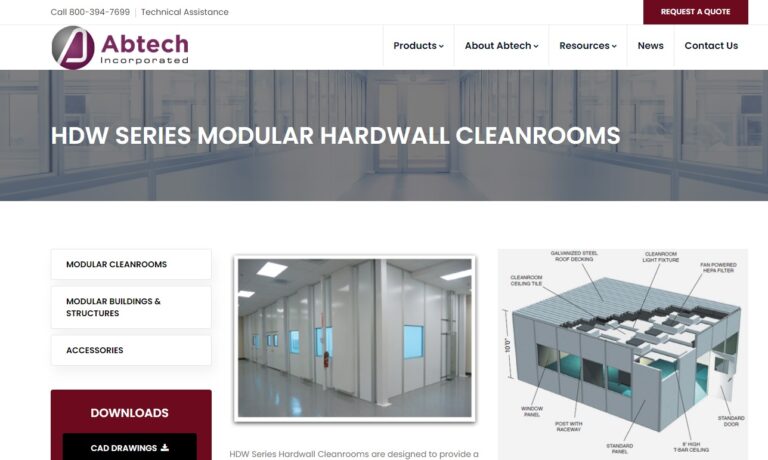

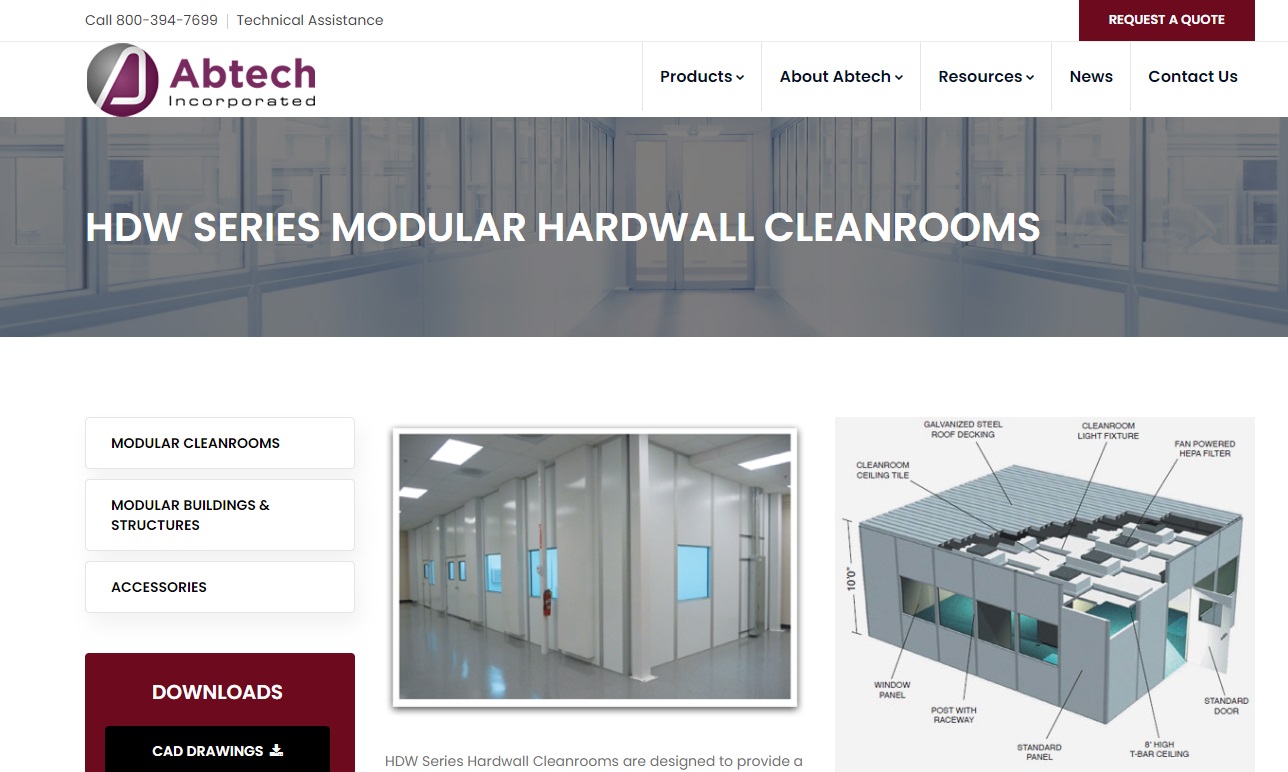

As a manufacturer of clean rooms, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

For the very best of clean rooms, look no further than Clean Rooms International! We can provide the ultimate in quality, customer service, durability, and unique designs just for you!

Cleanrooms By United is the industry’s premier manufacturer of modular clean room systems. We design, manufacture and install our clean rooms to meet our customers’ unique requirements. The custom, flexible, modular construction of our cleanrooms makes them easy to expand, reconfigure, or relocate as your cleanroom needs evolve.

Atmos-Tech Industries is a designer and manufacturer of cleanrooms and equipment for industries, including health care, pharmaceutical aerospace and automotive.

At MayAir Inc., we specialize in designing, engineering, and manufacturing high-performance clean rooms tailored to meet the most stringent contamination control requirements. With years of expertise, we provide comprehensive clean room solutions for various industries, including pharmaceuticals, electronics, biotechnology, and healthcare.

Our complete line of clean rooms will meet your needs. We are the experts of the clean room industry and our engineers can work with you to determine which clean room models work best for your business. We offer a variety of softwall, bio-clean, hardwall, and micro-clean options, all of which are manufactured with the highest standards. You will not be upset with our products. Contact us for more ...

Since 1976, we at Mitchell Technical Sales have been dedicated to delivering excellence in quality cleanroom design, manufacturing, installation, certification, and maintenance. Our journey has been marked by innovation and expertise, ensuring that every project we undertake reflects our commitment to precision and cutting-edge solutions.

More Class 1000 Clean Room Manufacturers

Components of a Class 1000 Cleanroom

A Class 1000 cleanroom—also called an ISO 6 cleanroom—is a controlled environment designed to maintain extremely low levels of airborne particulates, pollutants, and contaminants. The core components of a Class 1000 cleanroom are similar to those in other cleanroom classes, but with stricter specifications to meet the ISO 14644-1 standards for air quality. These environments are critical for industries such as semiconductor fabrication, pharmaceutical production, biotechnology research, and medical device manufacturing, where even microscopic particles can compromise product quality or safety.

- HEPA Filtration System: Class 1000 cleanrooms are equipped with high-efficiency particulate air (HEPA) filters, which are critical for removing at least 99.97% of airborne particles as small as 0.3 microns. In some cases, ultra-low penetration air (ULPA) filters are used for even greater filtration efficiency.

- Laminar Airflow: Many cleanrooms employ laminar or unidirectional airflow, ensuring continuous sweeping of airborne particulates away from sensitive processes. This is essential for cleanroom design to meet ISO classification standards.

- Positive Air Pressure: Maintaining positive pressure prevents unfiltered air and contaminants from entering the cleanroom when doors are opened.

- Environmental Controls: Stringent regulation of temperature and humidity is maintained. This reduces the risk of static discharge, microbial growth, and product defects.

- Cleanroom Construction Materials: Surfaces are constructed from non-shedding, easy-to-clean materials, such as stainless steel, epoxy-coated panels, and vinyl flooring. Selecting the right materials reduces particulate generation and supports GMP compliance.

- Airlocks and Gowning Rooms: Controlled entryways and gowning areas ensure personnel don appropriate cleanroom garments and minimize contamination risks.

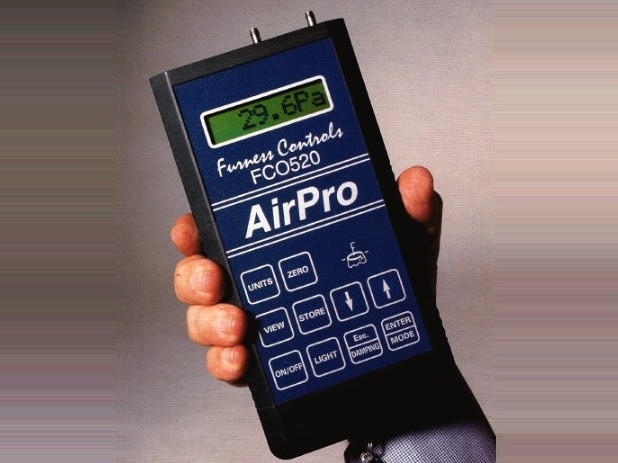

- Continuous Monitoring Systems: Advanced sensors and monitoring systems track particle counts, temperature, humidity, and pressure in real time, providing automated alerts for any deviations.

- Lighting and Utilities: Sealed, low-dust lighting fixtures and easy-to-clean utilities prevent the accumulation of particles.

- Cleanroom Equipment: Specialized, easy-to-sanitize furniture and equipment are selected to avoid particle generation and chemical off-gassing.

To achieve a lower maximum allowable particle count, a Class 1000 cleanroom may require additional components, such as more powerful air handling units, enhanced pre-filters, and more rigorous cleaning and maintenance protocols compared to lower-class cleanrooms (e.g., ISO 7 or Class 10,000). These stricter standards are essential for operations that demand near-sterile environments and high product yield.

What Are the Key Design Elements of a Class 1000 Cleanroom?

If you are evaluating cleanroom options, consider the following questions:

- Does your application require laminar or turbulent airflow patterns?

- What level of air exchange rate (ACH) is needed to maintain Class 1000 conditions?

- Are anti-static or ESD-safe features necessary for your processes?

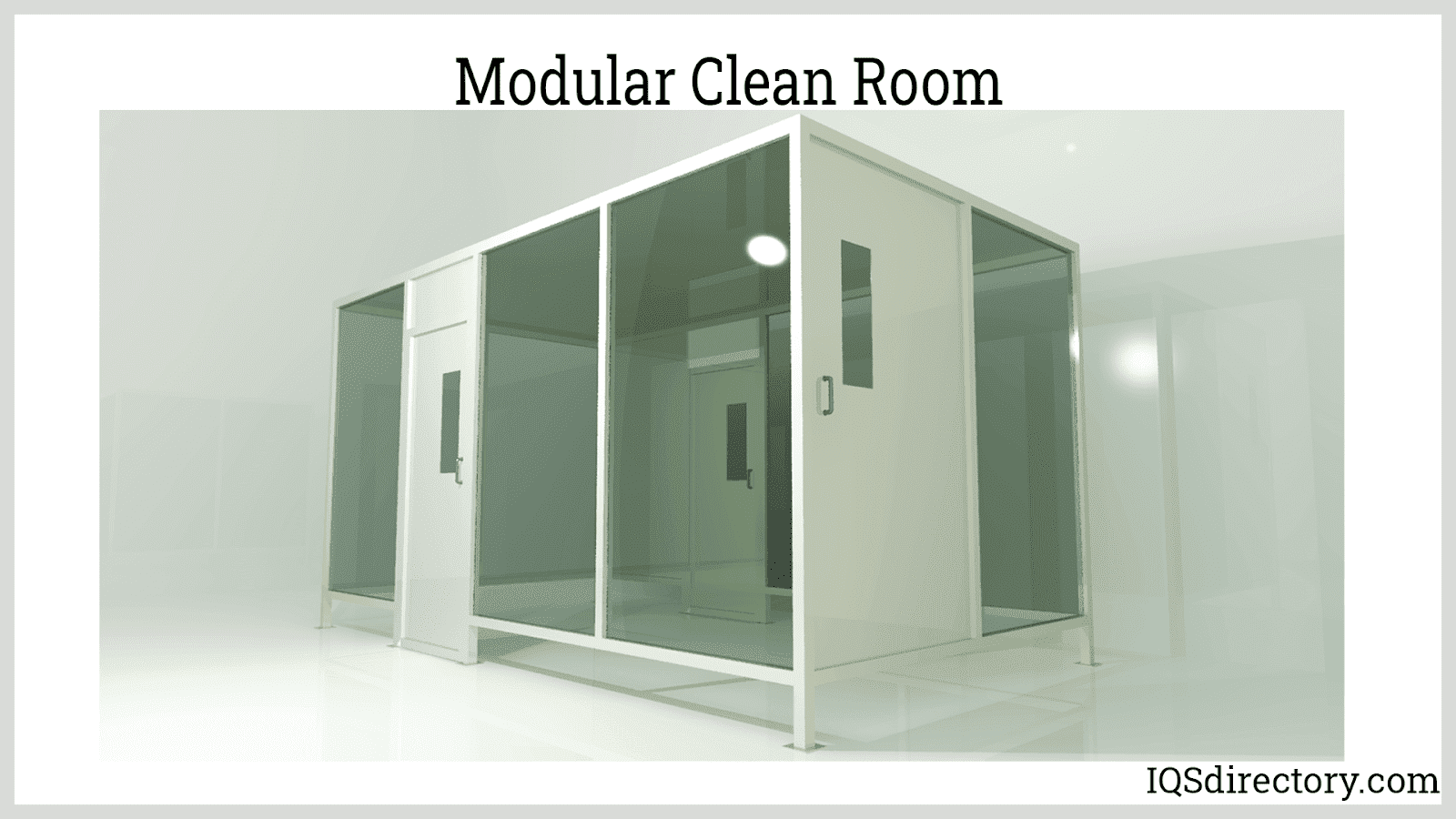

- Will your cleanroom require modular construction for flexibility and future expansion?

These factors play a critical role in cleanroom design and engineering decisions.

Variations of Class 1000 Cleanrooms

While the core function of a Class 1000 cleanroom is to provide a controlled, low-particulate environment, there are several ways these cleanrooms can be customized for distinct industry needs and processes. There are no formal sub-variants of the Class 1000 (ISO 6) designation, but practical variations emerge based on application requirements and regulatory guidelines.

- Material Selections: Cleanrooms for electronics or microelectronics manufacturing often use anti-static (ESD-safe) flooring, wall coatings, and workstations to prevent electrostatic discharge, which can damage sensitive components.

- Construction Methods: Options include modular cleanrooms for rapid deployment and scalability, or stick-built cleanrooms for permanent, highly customized installations.

- Pharmaceutical Cleanrooms: Facilities handling sterile compounding or drug production may incorporate stainless steel benches, pass-through chambers, and cleanroom-grade autoclaves to support rigorous cleaning and sterilization.

- Specialized HVAC and Filtration: Enhanced air handling systems and HEPA/ULPA filtration arrays may be implemented to address unique air quality or environmental control requirements.

- Integration of Automation: Robotics, automated material handling, and advanced monitoring systems can further reduce human-borne contamination and improve operational efficiency.

Are you seeking to customize a Class 1000 cleanroom for a specialized process? Contact expert cleanroom designers to discuss your application-specific needs.

Considerations Regarding Class 1000 Cleanrooms

When selecting or designing a Class 1000 cleanroom, several critical considerations should inform your decision. These include not only technical requirements but also long-term operational and compliance factors, especially as they relate to total cost of ownership and regulatory mandates.

- Cost of Construction and Installation: Building a Class 1000 cleanroom involves significant investment in HVAC systems, filtration, cleanroom-grade materials, and comprehensive monitoring systems. Costs are higher than for less stringent cleanroom classes due to enhanced requirements.

- Ongoing Maintenance and Operation: Maintaining ISO 6 standards requires frequent filter replacement, regular environmental monitoring, and rigorous cleaning. Labor and consumable costs should be factored into budget planning.

- Certification and Recertification: Any modification—such as adding new equipment, changing room layout, or expanding the facility—triggers a need for recertification to ensure compliance with ISO standards and, if applicable, GMP or FDA requirements.

- Personnel Training: Staff must be thoroughly trained in cleanroom protocols, gowning procedures, and contamination control best practices to maintain particle counts within allowable limits.

- Scalability and Flexibility: Consider whether your cleanroom design supports future expansion, reconfiguration, or technology upgrades as your operational needs evolve.

- Energy Efficiency: Advanced cleanrooms consume substantial energy for air handling and environmental control. Investing in energy-efficient systems can reduce long-term operational costs and support sustainability goals.

Are you trying to estimate the long-term costs and compliance requirements for a Class 1000 cleanroom project? Explore expert resources on cleanroom construction and certification.

Benefits of Class 1000 Cleanrooms

Investing in a Class 1000 cleanroom offers substantial operational, quality, and compliance advantages that can directly impact your business’s bottom line. Below, we outline key benefits and their implications for various industries.

Enhanced Product Quality and Consistency

Operating within a Class 1000 cleanroom environment significantly reduces airborne particle counts, leading to improved product reliability, yield, and uniformity. This is particularly important for semiconductor fabrication, pharmaceutical manufacturing, and medical device assembly.

Superior Contamination Control

With advanced HEPA filtration, positive air pressure, and strict gowning protocols, Class 1000 cleanrooms minimize the risk of contamination by dust, microbes, and chemical vapors. This is essential for processes sensitive to even the smallest environmental deviations.

Regulatory Compliance and Industry Standards

Class 1000 cleanrooms are designed to comply with international standards, such as ISO 14644-1, Good Manufacturing Practices (GMP), and FDA guidelines. Compliance supports product approvals, quality certifications, and entrance into regulated markets.

Increased Operational Efficiency

By reducing contamination events and minimizing product recalls or defects, cleanrooms support higher process efficiency, less rework, and lower operational costs. Automation and advanced monitoring further enhance productivity and throughput.

Improved Employee Safety and Comfort

Cleanrooms are designed to protect not only products but also personnel by controlling exposure to hazardous substances, biological agents, or volatile chemicals. This creates a safer, healthier working environment and can reduce occupational health risks.

Brand Reputation and Customer Trust

Consistent product quality and compliance with industry standards build trust with customers and end users, supporting long-term business growth and a solid market reputation.

Broader Market Access

Organizations with certified cleanroom facilities can serve clients in highly regulated sectors, such as aerospace, pharmaceuticals, or medical devices, expanding their business opportunities.

Scalability and Customization

Modern cleanroom designs, including modular Class 1000 systems, allow for fast scaling and customization to meet new process or capacity requirements.

Key Benefits at a Glance

- Improved cleanliness and product consistency

- Reduced contamination risk

- Compliance with ISO, GMP, and FDA regulations

- Safer working environment for staff

- Higher throughput and process efficiency

- Enhanced product value and customer satisfaction

Applications of Class 1000 Cleanrooms

Class 1000 cleanrooms serve critical roles across multiple high-tech and regulated industries where stringent environmental controls are essential. Whether you are researching cleanroom requirements for electronics, medical, or aerospace use, understanding industry-specific applications helps guide your purchasing and design decisions.

- Semiconductor Manufacturing: The fabrication of integrated circuits, microprocessors, and other electronic components demands ultra-clean environments to prevent defects that can affect device performance, yield, and reliability. Class 1000 cleanrooms are standard for photolithography, wafer processing, and assembly operations.

- Pharmaceutical Manufacturing: Sterile drug production, compounding, and packaging require controlled environments to prevent microbial and particulate contamination. Compliance with ISO 6/7/8 classifications is often mandated by regulatory agencies.

- Biotechnology: Research and production of biologics, recombinant proteins, and cell therapies depend on cleanroom controls to maintain sample purity and process integrity. Class 1000 cleanrooms are used for tissue culture, genetic engineering, and diagnostic kit assembly.

- Aerospace: Assembly of satellites, spacecraft, and sensitive avionics is performed in cleanrooms to prevent particulate contamination that could compromise mission-critical functions during launch or operation.

- Medical Device Manufacturing: Implantable devices, surgical instruments, and diagnostic equipment are manufactured in cleanroom environments to meet sterility and safety standards required for patient care.

- Microelectronics: The production of miniature sensors, MEMS devices, and nanotechnology components relies on ISO 6 cleanrooms to protect against dust and static, ensuring optimal performance and reliability.

- Optics and Laser Technology: Precision optical components, lenses, and laser assemblies are produced in cleanrooms to avoid defects caused by airborne particles or chemical contamination.

- Food and Beverage Processing: Specialty applications, such as aseptic packaging or high-purity ingredient handling, may use Class 1000 cleanrooms to ensure product safety and regulatory compliance.

- Automotive and Battery Manufacturing: Production of electric vehicle batteries, fuel cells, and critical sensors often takes place in cleanroom environments to improve product consistency and longevity.

How Do I Determine the Right Cleanroom Class for My Application?

Consider the following:

- What particle size and count thresholds are acceptable for your products?

- Are you subject to specific industry regulations (e.g., FDA, GMP, ISO)?

- What processes or materials are most vulnerable to contamination?

- Do you require additional features such as ESD control, modularity, or automation?

Not sure if Class 1000 is right for your process? Explore cleanroom classification standards and applications.

Choosing the Right Class 1000 Cleanroom Manufacturer

Choosing a Class 1000 cleanroom manufacturer or supplier is a critical decision that impacts your facility’s compliance, operational efficiency, and long-term ROI.

- Expertise and Experience: Review each manufacturer’s business profile to evaluate their experience in your industry, including successful installations, technical capabilities, and familiarity with relevant standards.

- Customization and Design Support: Leading manufacturers offer in-house engineering and design services to tailor cleanroom solutions to your process and regulatory requirements.

- Turnkey Solutions: Consider vendors that provide end-to-end project management, from design and construction to certification and ongoing maintenance.

- Compliance and Certification: Ensure the manufacturer adheres to ISO, GMP, and FDA guidelines, and can assist with documentation and validation processes.

- After-Sales Support and Service: Evaluate the scope of maintenance, warranty, and support services offered to maximize uptime and compliance post-installation.

Each Class 1000 cleanroom manufacturer has a business profile page highlighting their areas of experience and capabilities. Use the contact form provided to request additional information, discuss project requirements, or obtain a customized quote. Our patented website previewer allows you to quickly identify the specialties of each company, streamlining your vendor selection process.

Ready to Request a Quote?

Use our simple RFQ form to contact multiple Class 1000 cleanroom companies with a single submission. Compare capabilities, lead times, and pricing to make an informed purchasing decision.

Still Have Questions About Class 1000 Cleanrooms?

Explore further:

- How do I design a Class 1000 cleanroom?

- What are the construction best practices for ISO 6 cleanrooms?

- How do ISO, GMP, and FDA requirements impact cleanroom operations?

Whether you are evaluating cleanroom specifications for a new facility or seeking to upgrade your current environment to meet stricter standards, leveraging expert resources and connecting with experienced manufacturers will ensure long-term success in your cleanroom project.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services