A class 10000 clean room refers to United States Federal Standard 209. It classifies clean rooms from 1 to 100000, with a classification of 1 having the highest standards and 100000 being the least restrictive standards. Clean rooms are classified according to the number of particles they contain per cubic meter. Particulate matter in a clean room is measured in microns, one-millionth of a meter or micrometers, a measurement that is so small that it is beyond normal human vision. Read More…

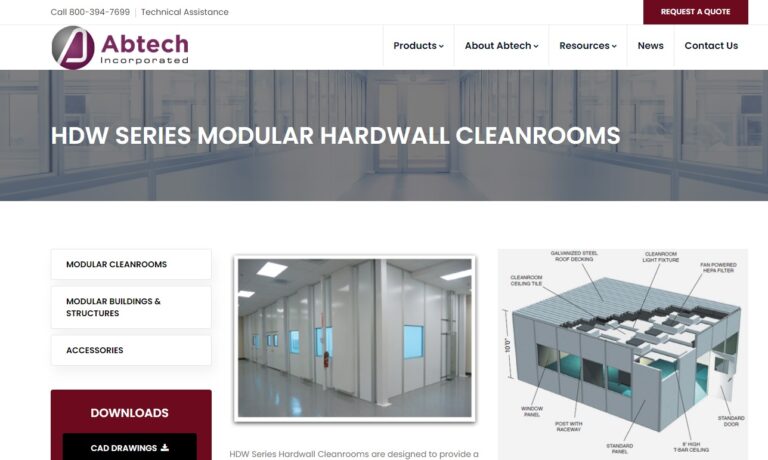

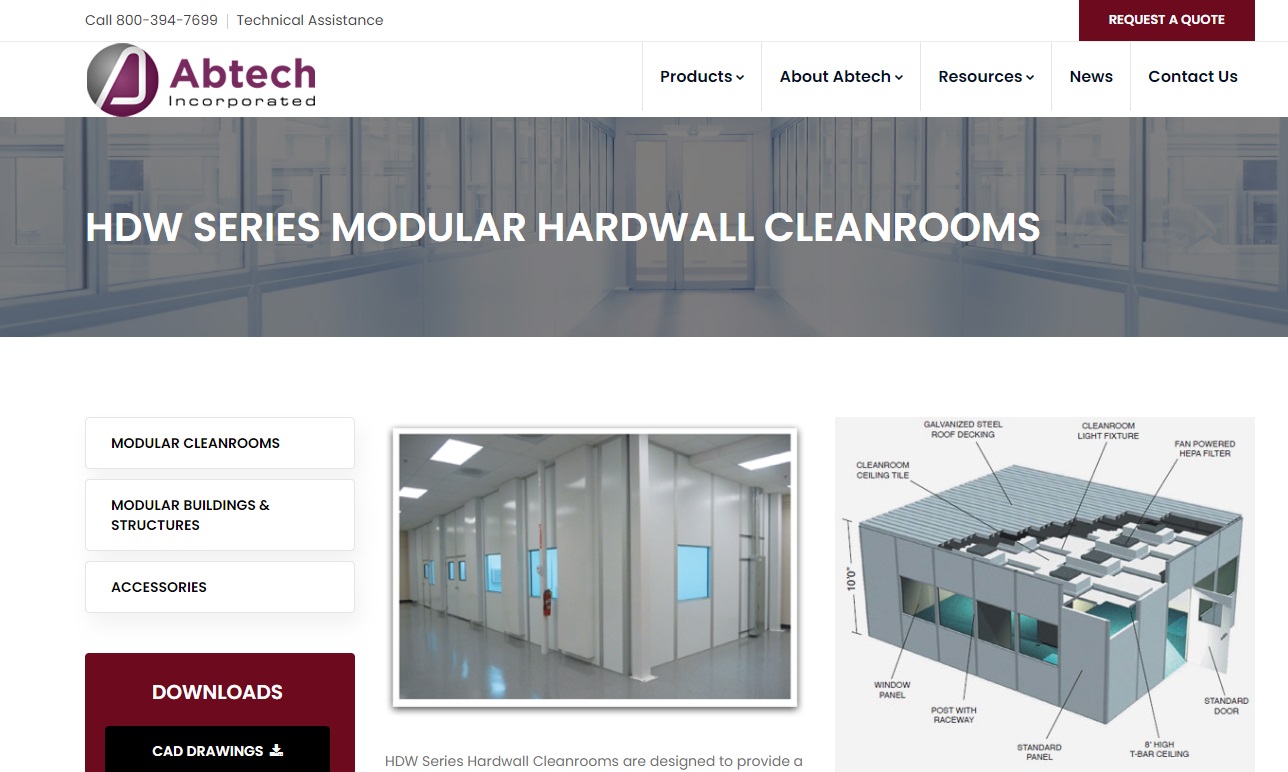

As a manufacturer of clean rooms, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

For the very best of clean rooms, look no further than Clean Rooms International! We can provide the ultimate in quality, customer service, durability, and unique designs just for you!

Cleanrooms By United is the industry’s premier manufacturer of modular clean room systems. We design, manufacture and install our clean rooms to meet our customers’ unique requirements. The custom, flexible, modular construction of our cleanrooms makes them easy to expand, reconfigure, or relocate as your cleanroom needs evolve.

Atmos-Tech Industries is a designer and manufacturer of cleanrooms and equipment for industries, including health care, pharmaceutical aerospace and automotive.

At MayAir Inc., we specialize in designing, engineering, and manufacturing high-performance clean rooms tailored to meet the most stringent contamination control requirements. With years of expertise, we provide comprehensive clean room solutions for various industries, including pharmaceuticals, electronics, biotechnology, and healthcare.

Our complete line of clean rooms will meet your needs. We are the experts of the clean room industry and our engineers can work with you to determine which clean room models work best for your business. We offer a variety of softwall, bio-clean, hardwall, and micro-clean options, all of which are manufactured with the highest standards. You will not be upset with our products. Contact us for more ...

Since 1976, we at Mitchell Technical Sales have been dedicated to delivering excellence in quality cleanroom design, manufacturing, installation, certification, and maintenance. Our journey has been marked by innovation and expertise, ensuring that every project we undertake reflects our commitment to precision and cutting-edge solutions.

More Class 10000 Clean Room Manufacturers

Class 10,000 Clean Rooms: A Comprehensive Guide to Design, Applications, and Supplier Selection

Clean rooms are scientifically engineered enclosures designed to perform highly sensitive research, manufacturing, and fabrication processes. The restrictive and controlled conditions of a clean room protect products, research samples, and processes that can easily be contaminated by the smallest particles of dirt, dust, or microbes. For this reason, strict environmental controls and close adherence to air quality standards, along with the use of specialized cleanroom apparel, are required to maintain compliance and achieve desired cleanliness levels.

Are you searching for detailed insights into class 10,000 clean rooms? Wondering what sets ISO class 7 (class 10,000) cleanrooms apart from more restrictive or less stringent classifications? This guide covers everything you need to know—from cleanroom design elements and regulatory standards to industry use cases, decision factors, and supplier selection tips.

The Elements of a Clean Room

The design of clean rooms involves strict control of the atmosphere, including the walls, air handling systems, flooring, ceiling, windows, lighting, and doors. The selection of cleanroom components and equipment—from HEPA filtration systems to modular panel construction—directly impacts a clean room’s classification according to ISO and Federal Standards.

Class 10,000 clean rooms (also known as ISO 7 cleanrooms) are one of the least restrictive controlled environments, allowing a particulate count of up to 352,000 particles of 0.5 microns or larger per cubic meter of air. This level of contamination control supports a wide range of critical processes while offering greater flexibility compared to more stringent classes like ISO 5 (class 100) or ISO 6 (class 1,000).

Cleanroom Apparel and Personal Protective Equipment (PPE)

Unlike higher-class cleanrooms—where full bunny suits, respirators, and strict gowning protocols are mandatory—workers in a class 10,000 clean room are permitted to wear their own clothing with additional coverings for shoes and hair, face masks, lab coats, and gloves. Cleanroom gloves are typically made of synthetic materials such as latex or nitrile, ensuring low particle shedding and high tactile sensitivity. Gloves, shoe covers, and hair nets are usually single-use and disposed of after each session to reduce the risk of cross-contamination.

Air Filtration and HVAC Systems

The foundation of any clean room is its air handling unit, which uses high-efficiency particulate air (HEPA) filters or ultra-low penetration air (ULPA) filters to remove airborne contaminants. HEPA filters are capable of trapping 99.99% of all particulate matter as small as 0.3 microns. In class 10,000 clean rooms, air handling units are commonly located in the ceiling or walls, with strategically placed vents to ensure laminar airflow and minimize turbulence. Advanced cleanroom HVAC systems also regulate temperature, humidity, and pressure differentials to maintain optimal environmental stability and compliance with GMP (Good Manufacturing Practice) or FDA requirements.

Lighting Solutions for Cleanrooms

All aspects of a clean room, including lighting, must be tightly sealed to prevent the infiltration of bacteria or particles. LED lighting is the industry standard due to its efficiency, longevity, and minimal heat output. Cleanroom light fixtures are designed for airtight installation and are often accessible for maintenance from outside the cleanroom envelope to preserve environmental integrity. The location and brightness of lighting are carefully engineered to eliminate shadows and support visual inspections critical to quality assurance in sensitive manufacturing and laboratory operations.

Entryways, Airlocks, and Pass-Through Chambers

For class 10,000 clean rooms, doors and entryways are available in a variety of widths and heights to suit the specific needs of the room and its equipment. Entry doors may feature observation windows and can be manual, automatic, sliding, or motorized for hands-free operation. In many cases, double-door airlocks or interlocked doors are installed to reduce pressure fluctuations and prevent unfiltered air from entering the cleanroom during ingress and egress.

Pass-through chambers, also called pass thrus or pass boxes, are essential features in cleanroom design. These small, cabinet-like structures are built into the wall and allow for the transfer of uncontaminated materials and tools into and out of the clean room without requiring staff to follow the full entry protocol. Pass-throughs minimize foot traffic and help maintain positive pressure, reducing the risk of contamination in critical environments.

Ceiling Grids and Modular Cleanroom Ceilings

The ceiling grid system is suspended by steel wires from the facility’s structure and supports modular ceiling panels, lighting, and filter units. Cleanroom ceiling tiles are fabricated from tightly sealed, non-porous materials—such as coated steel, aluminum, or high-pressure laminates—to ensure a secure fit and prevent the intrusion of contaminants from above. Modular ceiling grids provide flexibility for future expansion or reconfiguration, a key advantage for industries with evolving process requirements.

Wall Panels and Construction Materials

The selection of wall panels for a class 10,000 clean room is crucial for maintaining long-term cleanliness and structural integrity. Cleanroom walls are typically constructed from vinyl, high-pressure laminates, fiberglass reinforced plastic (FRP), or coated steel/aluminum. The internal core material—often polystyrene, gypsum, or isocyanurate—adds strength, insulation, and fire resistance. Smooth, seamless wall panels are preferred to minimize dust accumulation and allow for easy cleaning and disinfection in compliance with regulatory standards.

Class 10,000 Clean Room Specifications and Standards

Every cleanroom is classified according to international or federal standards based on the maximum allowable levels of airborne particulate contamination. Two of the most widely recognized standards are the ISO 14644-1 standard and the now largely superseded Federal Standard 209E. A class 10,000 clean room corresponds to ISO class 7, permitting up to 352,000 particles (≥0.5 microns) per cubic meter of air. This classification impacts everything from facility design and construction to operating protocols, monitoring, and validation requirements.

Air Change Rate (ACR) and Environmental Monitoring

The primary determinant for a cleanroom's classification is its air change rate (ACR)—the number of times the total air volume in the room is replaced with filtered air each hour. For a class 10,000 clean room, the recommended ACR is 45 to 60 air changes per hour. This high rate of airflow ensures the continuous removal of particulates, vapors, and airborne contaminants, maintaining a stable and predictable cleanroom environment.

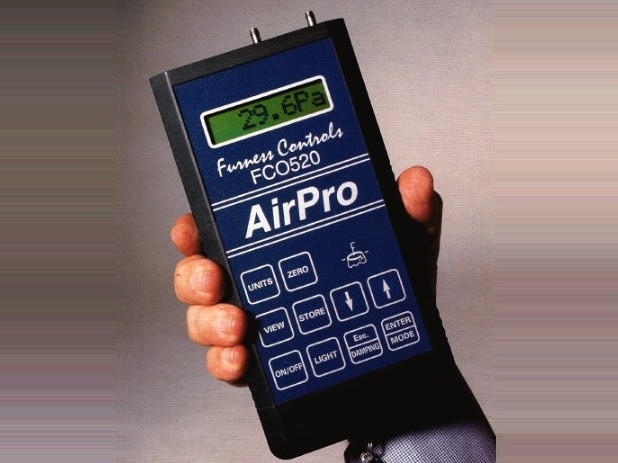

Environmental monitoring is essential for verifying ongoing compliance with cleanroom standards. Routine particle counts, temperature and humidity tracking, and microbial sampling are standard operating procedures. Many industries also implement real-time monitoring systems with data logging for regulatory reporting and process control.

Pressure Differentials and Zoning

Positive pressure is often maintained in class 10,000 clean rooms to prevent the infiltration of contaminants from adjacent uncontrolled spaces. Cleanrooms may also be subdivided into zones with varying cleanliness levels, separated by airlocks or pressure differentials, to further reduce the risk of cross-contamination during sensitive manufacturing and laboratory operations.

Regulatory Compliance and Validation

Depending on the application, class 10,000 clean rooms may need to comply with industry-specific regulations such as cGMP (current Good Manufacturing Practice), FDA, USP 797/800, EU GMP, and other international standards. Validation and periodic requalification—through airborne particle testing, airflow visualization, and microbial monitoring—are critical for demonstrating ongoing compliance and ensuring product safety and efficacy.

Industry Applications for Class 10,000 Clean Rooms

As technology advances and products become increasingly complex, clean rooms have become an indispensable part of modern manufacturing and research. Class 10,000 clean rooms (ISO class 7) are among the most widely used cleanroom classifications, providing a balanced combination of contamination control, operational flexibility, and cost-effectiveness. Industries that require controlled environments to ensure product quality, safety, and regulatory compliance include:

- Medical Device Manufacturing: Precision assembly and packaging of implants, diagnostic equipment, and surgical instruments.

- Electronics Manufacturing: Assembly of printed circuit boards (PCBs), semiconductors, and optical components.

- Pharmaceutical Compounding: Sterile compounding of drugs, vaccine production, and clinical trial sample preparation.

- Research Laboratories: Molecular biology, biochemistry, and materials science applications requiring contamination-free environments.

- Aerospace Product Development: Production and assembly of sensitive avionics, sensors, and propulsion systems.

- Cosmetics Production: Formulation and packaging of skin care products, makeup, and personal care items.

- Food and Beverage Processing: Specialty applications such as aseptic packaging, allergen-free production, and quality control testing.

- Automotive and Optics: Manufacture of high-precision optical lenses, sensors, and automotive electronics.

What Are the Key Benefits of a Class 10,000 Clean Room?

- Cost Efficiency: Provides a high level of contamination control without the significant capital and operational expenses associated with higher-class cleanrooms.

- Flexible Design: Modular construction and scalable systems allow for future expansion or reconfiguration as production needs evolve.

- Regulatory Compliance: Meets the requirements for a broad spectrum of industries, including medical, pharmaceutical, and electronics manufacturing.

- Enhanced Product Quality: Reduces defects and ensures the reliability and safety of critical products.

- Worker Safety and Comfort: Less restrictive gowning requirements improve worker mobility and comfort while maintaining essential protection.

Comparing Clean Room Classes: Is Class 10,000 Right for Your Application?

Choosing the appropriate cleanroom class is a critical decision that impacts facility design, operational protocols, and long-term product quality. While class 10,000 clean rooms offer a robust solution for many applications, some processes—such as sterile pharmaceutical manufacturing or nanotechnology fabrication—may require higher-level cleanrooms (e.g., ISO 5 or ISO 6). Conversely, less stringent environments might suffice for non-critical laboratory work or industrial assembly.

How do you determine which cleanroom classification best fits your needs? Consider the following questions as you evaluate your requirements:

- What are the regulatory requirements for your industry (e.g., FDA, cGMP, ISO 14644-1)?

- What level of particulate and microbial control is necessary to ensure product quality and compliance?

- What are your space, budget, and timeline constraints?

- Will your processes or products require future upgrades to a higher cleanroom class?

- How will you validate, monitor, and maintain your cleanroom to ensure ongoing compliance?

For more guidance, explore our comprehensive cleanroom standards guide or use our interactive cleanroom equipment selector tool.

Key Factors When Selecting a Class 10,000 Clean Room Supplier

Selecting a qualified, experienced class 10,000 clean room supplier is essential to achieving project success, regulatory compliance, and long-term operational efficiency. The right supplier will provide not only high-quality cleanroom products but also consulting, design, installation, validation, and ongoing support services.

What Should You Look for in a Cleanroom Supplier?

- Certifications and Compliance: Does the supplier demonstrate compliance with ISO, cGMP, FDA, or other relevant standards?

- Turnkey Solutions: Can they provide end-to-end services—including design, engineering, installation, and validation?

- Customization: Do they offer modular or custom cleanroom solutions tailored to your specific requirements?

- Technical Support: Will you have access to technical experts for troubleshooting, maintenance, and upgrades?

- References and Reputation: Are there case studies, client testimonials, and a proven track record of successful projects in your industry?

- Aftermarket Service: What warranties, support contracts, and maintenance packages are available?

To ensure the most constructive outcome when purchasing a 10,000 clean room from a reputable supplier, it is important to compare several companies using our directory of 10,000 clean room suppliers. Each company features a business profile page highlighting their areas of expertise, cleanroom capabilities, industry certifications, and manufacturing technologies. Use our integrated contact forms to directly communicate with suppliers for detailed information, technical consultation, or to request a competitive quote based on your project requirements.

Review each class 10,000 clean room company website using our proprietary website previewer for an at-a-glance understanding of their specialties, project portfolios, and service offerings. Then, use our simple RFQ form to contact multiple class 10,000 cleanroom businesses with a single, streamlined request.

Frequently Asked Questions About Class 10,000 Clean Rooms

- What is the difference between ISO class 7 and class 10,000? ISO class 7 (class 10,000) cleanrooms allow up to 352,000 particles ≥0.5μm per cubic meter, while lower-numbered classes (e.g., ISO 5/class 100) are more restrictive.

- How often should a class 10,000 clean room be tested or validated? Industry best practices recommend semi-annual or annual validation, with continuous environmental monitoring for critical applications.

- Can class 10,000 clean rooms be upgraded or expanded? Modular cleanroom systems allow for easy expansion or upgrades to higher cleanliness classes as production needs evolve.

- What are common contaminants in class 10,000 clean rooms? Airborne particulates, skin cells, hair, fibers, chemical vapors, and microbial contaminants are most common. Rigorous protocols for cleaning, gowning, and material handling are essential.

- How do I determine the total cost of ownership for a class 10,000 clean room? Factor in initial construction, equipment, validation, maintenance, energy use, and future upgrades. Request detailed quotes from multiple suppliers to compare options.

Ready to Get Started With Your Cleanroom Project?

Whether you are building a new facility, expanding your production capacity, or upgrading your existing cleanroom, choosing the right class 10,000 clean room solution is a critical investment in product quality, regulatory compliance, and operational efficiency. Our expert resources and supplier directory are designed to help you compare options, request quotes, and connect with experienced cleanroom manufacturers and service providers.

Begin your search today: Browse our class 10,000 clean room suppliers, learn more about cleanroom standards, or request a cleanroom quote to find the best solution for your facility and application.

Still have questions? Contact our cleanroom experts for personalized guidance and recommendations tailored to your industry, process, and regulatory needs.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services