Clean rooms provide a controlled and limited environment for the processing of products that are sensitive to microbial particles and microscopic organisms. The cleanliness of clean rooms is defined by the number of particles per cubic foot of air, which can be 10 particles at 0.5 microns (µ) per cubic foot of air up to 100,000 particles at 0.5 µ per cubic foot of air. The required micron levels for clean rooms have been established by the International Organization for Standardization (ISO) and the United States Standards 209E. Read More…

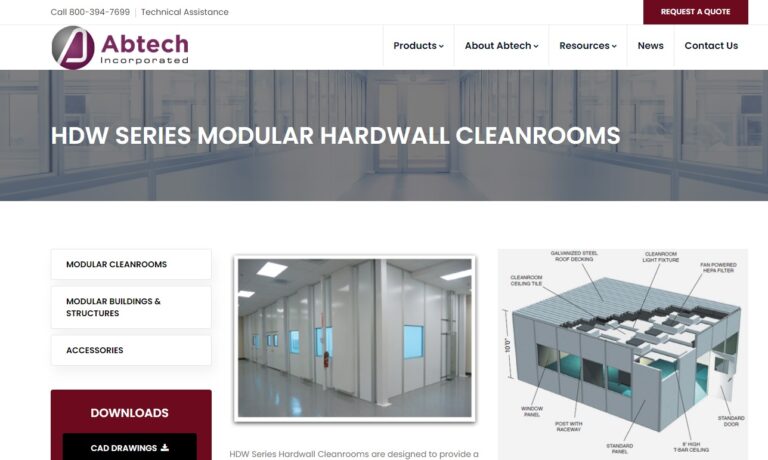

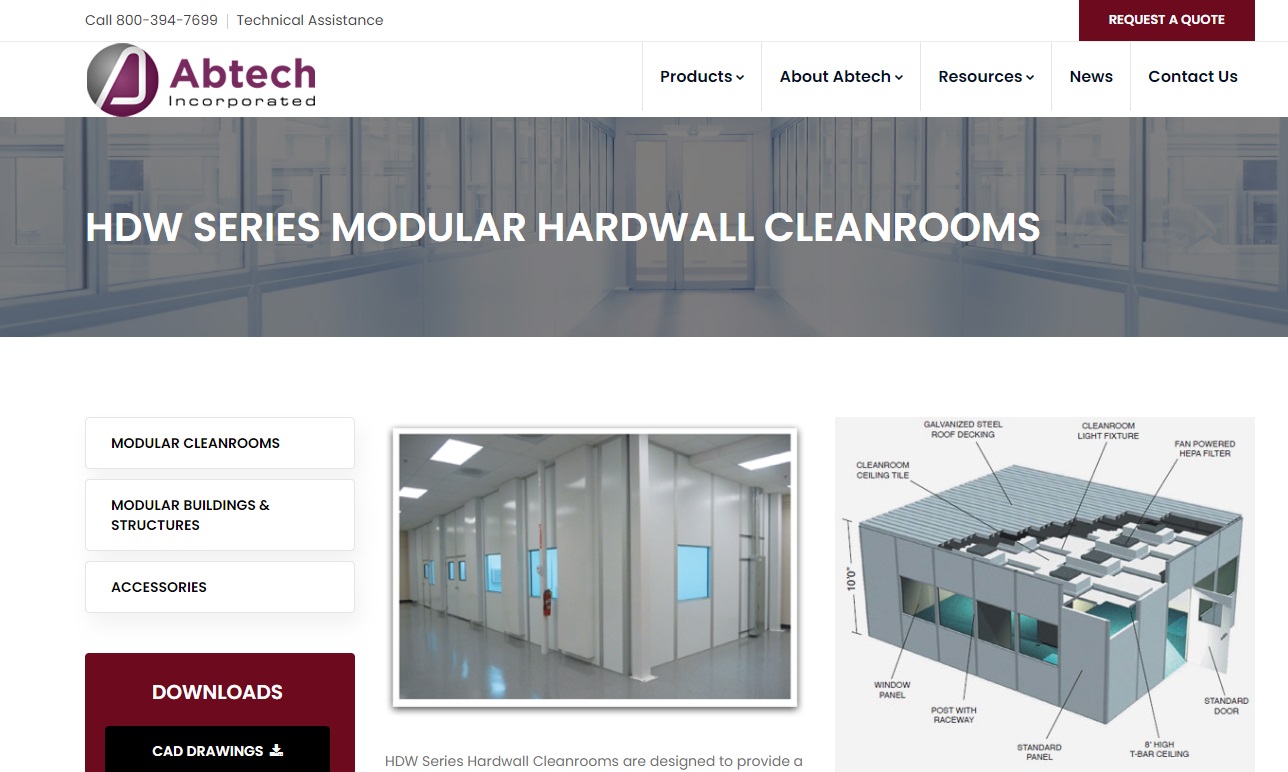

As a manufacturer of clean rooms, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

For the very best of clean rooms, look no further than Clean Rooms International! We can provide the ultimate in quality, customer service, durability, and unique designs just for you!

Cleanrooms By United is the industry’s premier manufacturer of modular clean room systems. We design, manufacture and install our clean rooms to meet our customers’ unique requirements. The custom, flexible, modular construction of our cleanrooms makes them easy to expand, reconfigure, or relocate as your cleanroom needs evolve.

Atmos-Tech Industries is a designer and manufacturer of cleanrooms and equipment for industries, including health care, pharmaceutical aerospace and automotive.

At MayAir Inc., we specialize in designing, engineering, and manufacturing high-performance clean rooms tailored to meet the most stringent contamination control requirements. With years of expertise, we provide comprehensive clean room solutions for various industries, including pharmaceuticals, electronics, biotechnology, and healthcare.

Our complete line of clean rooms will meet your needs. We are the experts of the clean room industry and our engineers can work with you to determine which clean room models work best for your business. We offer a variety of softwall, bio-clean, hardwall, and micro-clean options, all of which are manufactured with the highest standards. You will not be upset with our products. Contact us for more ...

Since 1976, we at Mitchell Technical Sales have been dedicated to delivering excellence in quality cleanroom design, manufacturing, installation, certification, and maintenance. Our journey has been marked by innovation and expertise, ensuring that every project we undertake reflects our commitment to precision and cutting-edge solutions.

More Modular Clean Room Manufacturers

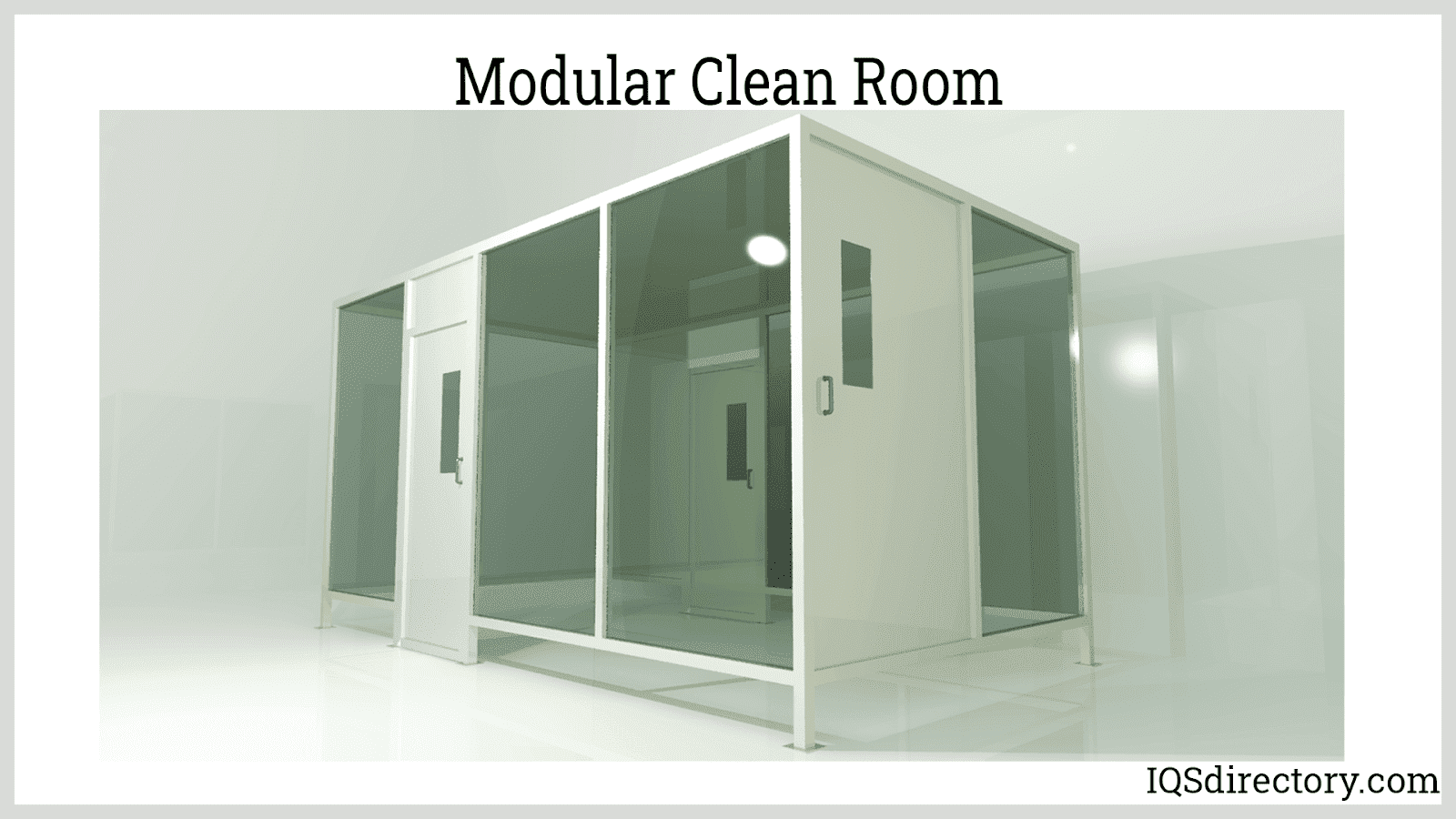

Aside from the definition ofclean rooms by their standards, there are different designs and configurations engineered to meet the needs of unique, unusual, and special circumstances. Modular clean rooms belong to this group due to their construction, size, and mobility. They are made of prefabricated panels assembled into a frame that can be rapidly installed and disassembled according to clean room specifications.

What is a Modular Clean Room?

A modular clean room is a type of clean room made of prefabricated materials that can be swiftly assembled and disassembled. They include all of the components that define a clean room, such as air filtering equipment, sealed walls and ceilings, and any required accessories in a more convenient and mobile size.

Modular clean rooms have rapidly become popular due to the rate at which the industry is changing and adapting. Much of this is due to the rise of technological advances that have found use in so many industries beyond phones, radios, and computers. As with all clean rooms, there are a wide variety of modular clean rooms in different sizes, designs, and shapes to meet the needs of any application and classification.

Modular Clean Room Components

Regardless of the size and mobility of modular clean rooms, they must have the necessary equipment to meet the definition of a clean room, which includes each of the assembly elements. The atmosphere in a clean room is controlled by a HVAC system that has a set of HEPA filters that removes 99.95% of particulate matter. The HEPA filter system is the most critical aspect of a clean room and defines its classification.

Beyond the filtration system are walls, ceilings, lighting, and floors that have their own set of requirements in regard to meeting clean room standards. The structural elements are defined by the materials used to make them.

- Modular Clean Room Panels– The panels for a modular clean room can be soft material such as plastic or vinyl, hard material, or clear, flat, and rigid material.

-

Frames for Modular Clean Rooms– The two most common materials for the frames of modular clean rooms are aluminum and steel.

-

Steel frame modular clean rooms use powder coated steel that is welded at the corners and ceiling. The flexibility of steel frame modular clean rooms makes it possible to use any type of panel material.

-

Aluminum frame modular clean rooms have an extruded anodized aluminum frame, which is exceptionally flexible and easy to place. They are customizable and very easy to install.

-

-

HEPA Air Filtration System– Although each of the various structural modular clean room components are important for sealing and enclosing the clean room, the HEPA filtration system is the most essential and necessary piece. HEPA filters control the microbial and particulate matter that enters the clean room. How they are engineered and placed determines the ISO classification of a modular clean room.

-

Modular Clean Room Walls– The material of the wall has several functions that influence how clean a cleanroom will be. Walls must have the ability to be easily cleaned and accessible. How sanitary and clean the walls of a modular cleanroom are is another determination of its classification.

-

Modular Clean Room Flooring– Every aspect of a modular clean room affects its classification. The floor, ceiling, and walls have to meet exacting standards to achieve its categorization. There are a wide variety of flooring materials, which include raised perforated metal, vinyl, coated epoxy, and rubber. The choice of which flooring to use is dependent on how the room will be used and the material to be tested.

- Ceiling for a Modular Clean Room– There are more specific requirements for ceilings for modular clean rooms because of the air handling units, lighting, filtration systems, and venting they have to support. Ceilings for modular clean rooms include grids made of aluminum or steel that are locked or spliced together with clips. The panels for the ceiling, made of materials similar to the wall panels, are supported by lips on the grid.

- Lighting– There are several varieties of lighting used for modular clean rooms and include fluorescent panels, strips, teardrops, or air flow through lights. The lighting for a modular clean room has to be designed to fit into the room such that it does not interfere with the air supply ducts or vents. The nature of the work of modular clean rooms requires lighting at a very high foot candle (fc) level, which is one lumen per square foot.

There is a close interplay between the fc and the air handling filtration system since the higher the fc, the more ineffective the filtration system may be. For most modular clean rooms, the fc is between 60 fc and 80 fc, which seems to be adequate to meet the necessary working and comfort level.

Types of Modular Clean Rooms

Modular clean rooms are differentiated by the type of walls they have, with hard and soft walls being the two general types. These two categories are general descriptors that cover a wide and ever-expanding range of modular clean rooms differing by size, accessories, and special features.

-

Soft Wall Modular Clean Rooms– Of the many types of modular clean rooms, the soft wall version is the most used due to its easy mobility and flexibility. They can be expanded and reconfigured as the need arises but still have the same sanitary features as their hard walled counterparts.

The standard sizes for soft wall clean rooms is from 8x8 to 12x24, with ISO classifications of Class 6 to Class 8. For special circumstances, these standard sizes can be customized to meet unique conditions. One of the positive features of modular clean rooms is how easily they can be customized to meet individual manufacturing requirements.

-

Hard Wall Modular Clean Room– The construction of a hard wall modular clean room consists of posts with hard walls mounted between them. The hard walls allow for an increased volume of air, which helps in reducing particulate matter. They can be used for applications where control of the temperature and humidity are essential.

Hard wall modular clean rooms have a slightly higher ISO classification from Class 5 to Class 8. Every aspect of a hard wall clean room can be customized down to the types of electrical outlets. They can be designed with gowning rooms, pass throughs, and airlocks.

Modular clean rooms are an inexpensive and practical solution for creating sanitized, contaminant-free environments for working on sensitive instruments that can be damaged by particulate matter or microbials. They are easy to set up and install and can be viable and productive in a few hours.

Choosing the Right Modular Clean Room Supplier

To ensure the most constructive outcome when purchasing a modular clean room from a modular clean room supplier, it is important to compare several companies using our directory of modular clean room suppliers. Each modular clean room company has a business profile page that highlights their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each modular clean room business website using our patented website previewer for a better understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple modular clean room businesses with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services